Process Chemistry

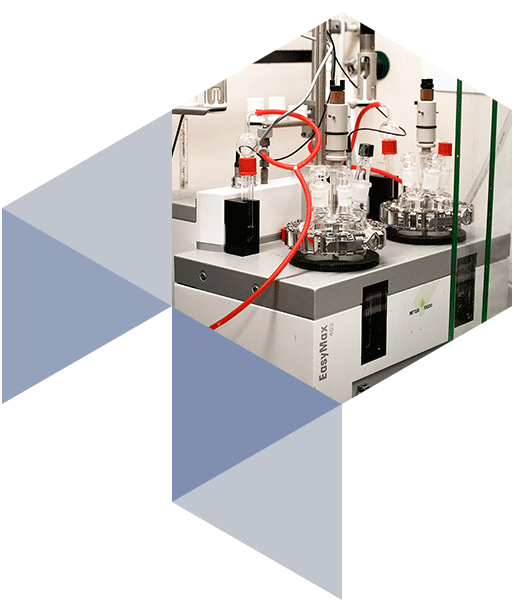

Our experienced team of Ph.D. Process Chemists will work to develop your chemistry into robust and commercially viable processes. This veteran team has scaled-up and optimized hundreds of challenging chemical processes. The Process Chemistry group supports each other and works closely with the Manufacturing and Process Engineering teams to overcome chemical and engineering issues.

Their work is supported by a host of analytical tools, including a 400 MHz NMR, LC/MS, HPLC, UPLC, DSC, TGA, XPRD, etc. The Process Chemistry team also works closely with an outstanding Analytical Research team that is engaged at the onset of the development work allowing the Analytical Team to not only help support the Process Group, but will also allow them to take an early look at your molecule, which helps them develop robust analytical methods later.

Request for Information

Rely on our expertise to accelerate your project from preclinical to commercialization, fast. Connect with our team and learn how we can help expedite your project to the next phase.