Regis Facility Tour

Regis Technologies has maintained a policy of regular reinvestment to keep our facility up-to-date and increase our capabilities to better serve our customers' needs.

Take a virtual tour of our facility through the photo gallery below. Interested in visiting us? Contact us to, schedule a visit.

Facility Tour

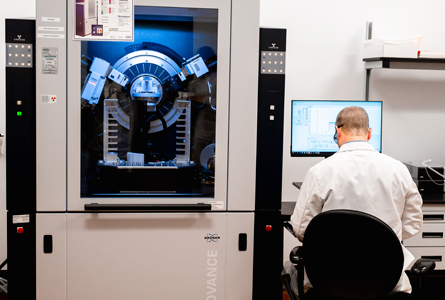

Solid State Chemistry Lab

State-of-the-art equipment, such as an XRPD, DSC, TGA, and more, provide salt, cocrystal, and polymorph screening and selection activities to provide suitable crystallization processes during all development phases. Learn more about our solid state chemistry characterization, screening, and selection services.

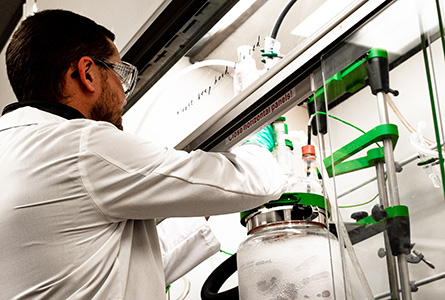

Synthetic Labs

Regis Process Chemists develop processes for safe, consistent and cost-effective processes. When transferring in chemistry, our process chemists to obtain proof of principle and gain experience with a given set of reactions prior to scale-up.

Kilo-Scale Labs

The kilo lab can be either the starting point for a project, or the permanent residence for a low-volume project. Our design assures complete compliance with cGMP guidelines, offers maximum protection against cross contamination, and allows chemists to handle hazardous materials with confidence. The facility is divided into three completely enclosed suites, each containing a hood and workspace. Incoming air is purified via 99.99% HEPA filters, and the individual rooms are maintained at a positive pressure relative to the corridor.

Glass Reactor Suite

The suite contains two 63 liter glass reactor systems. These systems feature insulated, glass lined steel jacketed bodies and all glass domes with attached reflux and stripping condensers. The robust variable speed agitation systems are comprised of Teflon lined stainless steel shafts with all Teflon anchor type stirring blades. The reactors utilize single fluid heating/cooling with a temperature range of -20°C to 120°C.

500 Gallon Reactor Suite

Regis currently has eight fully equipped reactor suites with Reactor sizes ranging from 25 to 500 gallons. Each suite contains a pair of Pfaudler glass-lined reactors and centrifuge or filter dryer for product isolation. Additional equipment, such as portable tanks and filter presses, may be moved in as needed.

Regis’ Reactor Suites are designed as individual manufacturing areas, thereby reducing the chance of cross contamination.

Cryogenic Reactor Suite

Regis’ cryogenic reactor suite contains a 150-gallon Hastelloy reactor. This vessel is used for enantioselective, site-specific additions and other low temperature reactions, including lithiations. The reactor has a range of -85°C to 100°C.

Product Isolation: Contained Filter Dryer

Regis has five GL Filtration Contained filter dryers. These dryers contain an Agitated Nutsche filter with a glove box for contained material discharge. This equipment allows us to run Safebridge 3A compounds in a contained process train in our facility.

Product Isolation: Centrifuge

A centrifuge is typically used for isolating products or intermediates. All centrifuges are made of 316 stainless steel.

Polypropylene and 316 stainless steel filter presses are also available.

Potent Compound Suite

Regis' Potent Compound Suite (PCS) is ready to host your project. Regis aims to serve the growing oncology market as more companies look to advance their lead candidates into the clinic.

Temperature Monitor

Chemists and technicians manually enter all critical temperatures into batch records. In addition, temperatures for all production equipment and refrigerators/freezers are continuously monitored via a data logging system.

Finishing Area

Isolated products are transferred to a finishing room for drying, grinding, and packaging. Because contamination is a particular concern at this point, access to this area is strictly controlled. The hallway is maintained at a positive pressure relative to the entire facility, including the drying rooms. Each of the five drying rooms has its own supply of 99.99% HEPA-filtered, ISO class 8 equivalent.

Drying Equipment

A variety of drying equipment is available, including three sizes of Stokes and United-McGill ovens. Our drying/finishing area is class 100,000.

Lyophilizer

Regis maintains one finishing room with Virtis 6 liter and 45 liter capacity lyophilizers. This allows recovery of products from water in an area with class 100,000 air.

Quality Control Laboratory

Our fully equipped QC lab operates in two shifts, as does our production team. Most required analytical work may be performed in-house, ensuring rapid turnaround for our clients.

Major equipment includes: one Agilent 1290 LC/MS, four Agilent 1290 UPLCs, eight Agilent 1200 HPLCs, two Agilent 1200/Alltech ELSD 3300, one Agilent 1200 HPLC/Thermo Corona Veo CAD, two Agilent 1260 HPLC/Thermo Corona Veo CAD, twelve 1260 HPLCs, two Agilent 6890 GCs with G1888 Headspaces, two Agilent 7890 GCs with G1888 Headspaces, one Agilent 7890 GC with G7679A Headspace and Agilent 5975C MSD, two Agilent 7890B GCs with 7697A Headspaces, Thermo Fisher Trace 1310 GC with TriPlus RSH Headspace, Thermo Fisher iCAP TQ ICP-MS, two Perkin Elmer FTIRs (Spectrum 100 and Spectrum Two), two Malvern MS3000 Particle Size Analyzers, one Dionex ICS-6000 with Conductivity Detector and KOH Eluent Generator, two Mettler Toledo DSCs (DSC 1 and DSC 3), one TA Discovery TGA, one Rudolph Autopol V Plus Autopolarimeter, two Mettler Toledo Halogen Moisture Analyzer, and two Hitachi U-2910 Spectrophotometers.

Cleaned Equipment Storage

All ancillary equipment is cleaned in a separate washing room before being moved to this room.